compressive strength of concrete cylinder test pdf|compressive strength formula for cylinder : trade Calculate the compressive strength of the specimen by dividing the maximum load carried by the specimen during the test by the average cross-sectional area determined as described . webR$ 13,85. Incluir na lista de compras. Tauste. Sashimi de Salmão 120g. R$ 21,59. Incluir na lista de compras. Tauste. Espetinho Kafta Tauste Congelado Aprox. 7un 850g - Limite de 5.1 Kg por compra. R$ 22,86.

{plog:ftitle_list}

Resultado da Watch the best Five Nights at Freddy's videos in the world for free on Rule34video.com The hottest videos and hardcore sex in the best Five Nights at Freddy's movies.

Scope 1.1 This test method covers determination of compressive strength of cylindrical concrete specimens such as molded cylinders and drilled cores. It is limited to concrete .Calculate the compressive strength of the specimen by dividing the maximum load carried by the specimen during the test by the average cross-sectional area determined as described .

1.1 This test method covers the determination of strength of cylindrical concrete specimens that have been molded in place using special molds attached to formwork.Con-crete compressive strength requirements can vary from 2500 psi (17 MPa) for residential concrete to 4000 psi (28 MPa) and higher in commercial structures. Higher strengths up to and .

1.1 This test method covers determination of compressive strength of cylindrical concrete specimens such as molded cylinders and drilled cores. It is limited to concrete .This guide summarizes practices for obtaining cores and interpreting core compressive strength test results. Factors that affect in-place concrete strength are reviewed so sampling .1.1 This test method covers determination of compressive crete Aggregates for Use in Construction and Criteria for strength of cylindrical concrete specimens such as molded . Inspect the cylinder in accordance with ASTM C 39 (Section 6, SPECIMENS) and notify the Lab supervisor of any imperfections that might make the cylinder not suitable for .

Field-cured cylinders are tested for estimating the in-place concrete strength. Procedures for standard-curing and field-curing are described in ASTM C31. Cylindrical specimens are tested .

The testing revealed that: (1) time-of-set of SCC was faster than for ordinary portland cement concrete by about 100 min, as was the rate of slump loss; (2) the compressive and splitting tensile .

strength is measured by breaking cylindrical concrete specimens in a compression-testing machine. Compressive strength is calculated from the failure load divided by the cross-sectional area resisting the load and reported in units of pound-force per square inch (psi) or megapascals (MPa). Concrete compressive strength can vary from 2500 psi (17COMPRESSIVE STRENGTH OF CONCRETE 1. Objective . (ACI standards use cylinder of diameter 150 mm and height 300 mm). The characteristic strength is defined as the strength of the concrete below which not more than 5% of the test results are expected to fall. . Fig. 2: Compression Testing Machine The testing machine may be of any reliable type .The conversion factors for the compressive strength between the core and the same size cast specimen was proposed for 150 × 300 mm and 100 × 100 mm specimen sizes. KEYWORDS air-entrained, concrete, compressive, strength, core, cylinder, size effect, testing 1 | INTRODUCTION Compressive strength is one of the most important properties of concrete.COMPRESSION TESTING OF CONCRETE CYLINDERS A ND CORES Rev. 0 1 1. PROCEDURE OVERVIEW This procedure is to be used for determining the compressive strength of concrete cylinders and cores . After preparing the ends, a compressive axial load will be applied to the samples at a continuous rate until failure occurs.

Concrete Compressive Strength Testing. Compression testing of concrete cylinders is the final step in this process and is performed following the standard test method ASTM C39/AASHTO T 22. The prepared concrete test cylinders are placed in a concrete compression machine and loaded axially at controlled rates until failure.ASTM C39 Procedure. 1. Bring the cylinders out of the moisture room, keeping them covered with wet burlap to keep them moist. Check the cylinders over for defects (holes, cracks, crumbliness) as you set them on the table, use your straight edge and nail to check for planeness, and set the ones with ends that are not plane aside to be saw cut.CIP 35 - Testing Compressive Strength of Concrete . Low Concrete Cylinder Strength. 2003, 2014 References 1. ASTM C 31, C 39, C 617, C 1077, C 1231, Annual Book of ASTM Standards, Volume 04.02, ASTM, West . CIP 35.pdf .compressive strength f c′. The latter can be directly substituted into conventional strength equations with customary strength reduction factors for strength evaluation of an existing structure. It is inappropriate to use procedures for determining the equivalent specified concrete strength to assess whether concrete strength in a new .

Compressive Strength of Cylindrical Concrete Specimens1 . 4.4 The individual who tests concrete cylinders for accep-tance testing shall have demonstrated a knowledge and ability to perform the test procedure equivalent to the minimum guidelines for certification of Concrete Laboratory Technician, Concrete compression is a complex phenomenon; a lot of factors influence the behavior of concrete under such loading. Three important factors affect concrete compression: the specimen size, geometry, and friction at its ends, all affect the observed results.At least two cylinders are tested at the same age and the average strength is reported as the test result to the nearest 10 psi (0.1 MPa) The technician carrying out the test should record the date they were received at the lab, the test date, specimen identification, cylinder diameter, test age, maximum load applied, compressive strength, type .

What happens if the concrete compressive strength is too low? If your concrete fails to achieve the designated compressive strength, as determined by 28-day concrete cylinder tests, it can be due to several factors: Improper cylinder handling, curing, and testing (the most common reason for low strength results). For over 80 years, ASTM C39 has been the industry standard test method for testing the compressive strength of concrete cylinder specimens. In this article, we cover the basics, including: The importance of ASTM C39; Recommended ASTM C39 supplies and equipment; Test procedure and results; The Importance of ASTM C39 for Compressive .Section 2 — Part I, Determining Compressive Strength of Cylindrical Concrete Specimens Texas Department of Transportation 3 06/00–06/08 Section 2 Part I, Determining Compressive Strength of Cylindrical Concrete Specimens This part determines compressive strength of cylindrical concrete specimens such as molded cylinders and drilled cores.

C 873 Test Method for Compressive Strength of Concrete Cylinders Cast in Place in Cylindrical Molds C 1077 Practice for LaboratoriesTesting Concrete and Con-crete Aggregates for Use in Construction and Criteria for Laboratory Evaluation C 1231/C 1231M Practice for Use of Unbonded Caps in Determination of Compressive Strength of Hardened Con-The MegaForce Concrete Testing System works with compression machines that operate up to 69 MPa or 10,000psi. Depending on the indicator chosen with the system, automated compressive strength test reports are generated, .

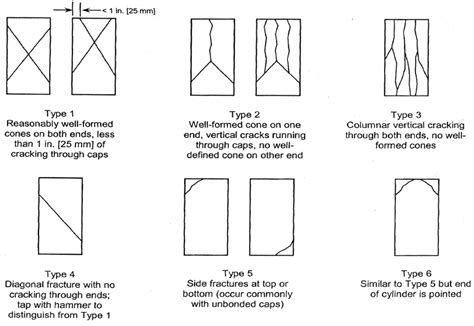

types of concrete cylinder breaks

concrete cylinder testing procedure

Based on the early strength, many studies have been conducted to predict and analyze the compressive strength of concrete or cement mortar at 28 days or other days [14][15] [16] [17][18]. The .

compressive strength testing at one test for each 150 yd3 of . Fig. 2: The test agency made seven 4 x 8 in. concrete cylinders. Two cylinders were tested at 7 days, three cylinders were tested at 28 days, and two hold cylinders remained available for testing at later age if neededC 1077 Practice for Laboratories Testing Concrete and Concrete Aggregates for Use in Construction and Criteria for Laboratory Evaluation2 C 1231/C 1231M Practice for Use of Unbonded Caps in Determination of Compressive Strength of Hardened Concrete Cylinders2 E 4 Practices for Force Verification of Testing Machines3 E 74 Practice for .

concrete cylinder testing near me

4.1 Cast-in-place cylinder strength relates to the strength of concrete in the structure due to the similarity of curing conditions because the cylinder is cured within the slab. However, due to differences in moisture condition, degree of consolidation, specimen size, and length-diameter ratio, there is not a unique relationship between the strength of cast-in-place .

concrete cylinder size chart

Personnel performing this test must hold current certification in Strength Testing by either ACI, MnDOT or WisDOT. 1407.3 SIGNIFICANCE and USE . This test is performed in the laboratory to determine if the strength of concrete meets specification requirements. It is used as an indication of the potential of the materials used in a structure.IS:516-1959 Indian Standard METHODS OF TESTS FOR STRENGTH OF CONCRETE o. FOREWORD 0.1 This Indian Standard was adopted by the Indian Standards Institution on 10 November 1959, after the draft finalized by the Cement and Concrete Sectional Committee had been approved by the Building Division Council. 0.2 Testing plays an important role in . The compressive strength of concrete is highly influenced by the properties of test specimens, such as size and moisture content. This paper presents the results of compression tests on more than . When determining the characteristic compressive strength of any concrete with given composition from its mean compressive strength according to the European product standards (EN 206:2013 .

Practice for Making and Curing Concrete Test Specimens in the Field. For estimating the in-place concrete strength, ASTM C 31 provides procedures for field-cured specimens. Cylindrical specimens are tested in accordance with ASTM C 39, Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens.

concrete cylinder failure types

Compressive Strength Test of Concrete Purpose of the Compressive Strength Test. The compressive strength test of concrete serves a critical purpose in assessing the durability and quality of concrete structures. This test is conducted to measure the maximum load-bearing capacity of a concrete cube or cylinder, typically sampled from a construction site, and to .

Ilustrações . Fundos . Texturas . Padrões . Cartoons . Clip art . Desenhos . Símbolos e sinais .

compressive strength of concrete cylinder test pdf|compressive strength formula for cylinder